Mortar

High-Performance Mortars for Durable, Efficient, and Sustainable Construction

At Page International, we supply premium mortar systems engineered for the realities of construction across Cameroon and the CEMAC region. Our mortars are produced under controlled factory conditions to deliver consistent strength, excellent workability, and long-term durability. Whether you are building housing, commercial buildings, bridges, or restoring heritage masonry, our mortars give you dependable bonding, cleaner finishes, and reduced site waste.

Our Product Range

We manufacture and offer a range of mortar formulations to meet common and specialised needs in the region, including general-purpose masonry mortar, high-bond structural mortar, finishing and plaster mortars, and dry-silo delivery options for high-volume sites. Each product is available as ready-to-use tubs, bagged dry mixes, or silo-fed dry material for on-site automated mixing. Formulations are tailored for local climatic conditions, aggregate availability, and common substrate types used in CEMAC construction.

Ready-to-Use and Dry Mortar Solutions

Factory-produced ready-to-use mortars remove the variability of on-site mixing. Each batch is precisely blended to ensure uniform cement content, sand grading, and additives. The result is consistent adhesion, reduced rework, and faster laying rates. For larger projects we provide dry-mortar delivered into on-site silos. The silo system automatically meters and mixes the mortar, producing a continuous, uniform supply on demand, which improves safety and reduces manual handling.

Sustainable Mortar Production

Sustainability is integral to our mortar strategy. We reduce embodied carbon by optimising cement content and by incorporating supplementary cementitious materials where appropriate, including GGBS and other industrial by-products that meet engineering requirements. Our factory production minimizes on-site waste, and silo or tub delivery reduces packaging and leftover mix disposal. We also offer recycled sand blends for non-structural uses where suitable, enabling projects to lower material footprint without sacrificing performance.

Performance and Typical Properties

Mortar performance depends on formulation, application and curing. Our product families are engineered to deliver predictable results in the CEMAC climate. Typical achievable properties vary by mix, however clients can expect consistent compressive and adhesion performance tailored to the application, for example masonry, rendering, or structural repair. All mixes are tested in our QA lab for particle grading, water retention, workability and hardened strength. We provide test certificates on request and can produce mixes to meet specific project performance targets.

Applications

Page International mortar is suitable for:

Bricklaying and blockwork for load-bearing and non-load-bearing walls.

Stone masonry, including structural and decorative stonework.

Internal and external rendering, plastering and finishing coats.

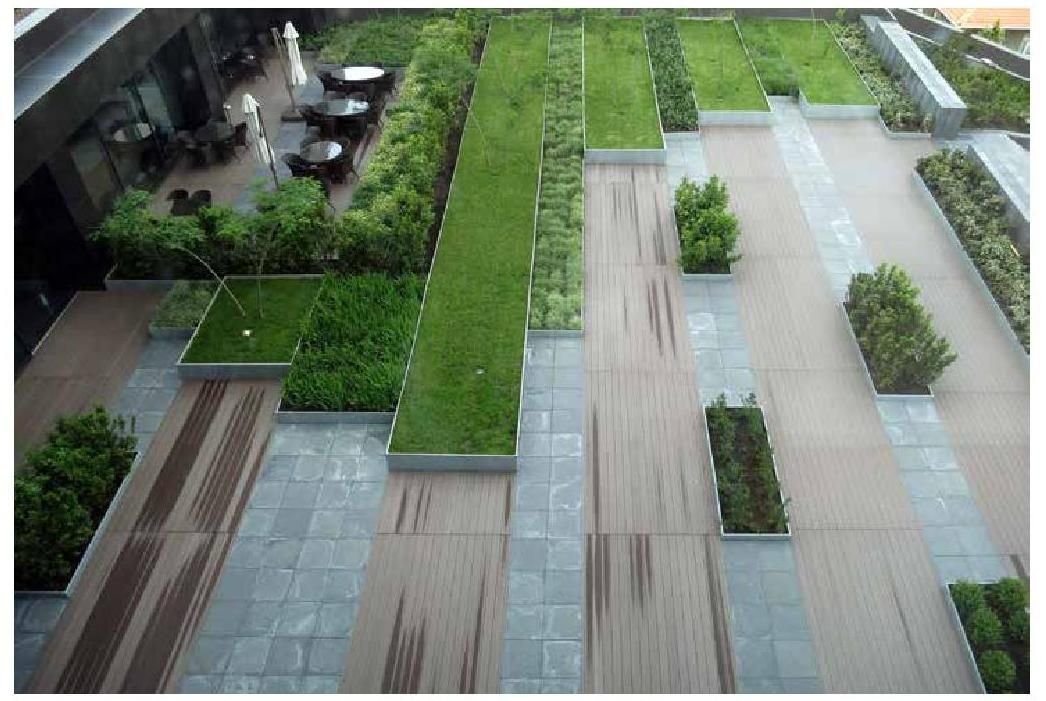

Flooring bed and parquet backer applications where specified.

Repair mortars for crack injection preparation and masonry restoration.

Each application receives a recommended mix specification and placement guidance to ensure correct performance and durability.

Site Guidance and Best Practice

Correct application is as important as the mix. We support clients with practical guidance on substrate preparation, joint sizing, bed thickness, and curing. Mortar should be applied onto clean, dampened surfaces. For best results, follow manufacturer guidelines for open time and re-tempering. In hot or dry conditions common in parts of CEMAC, we recommend shading, pre-wetting of masonry units, and controlled curing, to avoid rapid water loss that weakens bond strength. Our technical team can provide on-site training and supervision for critical placements.

Dry Silo Mortar Systems for High-Volume Projects

For housing estates, large commercial blocks or infrastructure sites that require continuous mortar supply, our Dry Silo Mortar Systems are a cost-effective option. A silo installation provides a sealed supply of dry mortar, automated proportioning and mixing, and a push-button supply of fresh mortar with uniform consistency. Benefits include reduced labor, less waste, better hygiene on site, and faster laying productivity. We manage silo installation, commissioning and ongoing supply logistics.

Quality Assurance and Testing

Quality control is integral to our production process. We operate an on-site laboratory where each batch is sampled and checked for gradation, silt content, moisture, and workability. Hardened samples are tested to verify compressive strength where needed. Material certificates and batch traceability are supplied with deliveries, enabling site teams and engineers to retain records for audit, tender and compliance purposes.

Packing, Storage and Delivery

Mortar is available in bulk silo supply, 25 kg and 40 kg bag formats, and ready-mix tubs for immediate use. Bags should be stored dry, off the ground, and protected from sun and rain. For best performance use bags within recommended shelf life. Silo deliveries are scheduled to match project phasing, and our logistics team coordinates deliveries across Cameroon and the CEMAC zone to meet site access constraints and sequencing requirements.

Health, Safety and Environmental Notes

Our mortars contain cementitious materials and must be handled with appropriate PPE including gloves, eye protection and masks when dust is generated. Follow local safety regulations for handling and disposal. Curing water runoff is managed to avoid sediment discharge to drains or watercourses. We provide safety data sheets and environmental guidance for contractors and project managers on request.

Technical Support and Trial Mixes

Page International provides technical support from project inception to completion. We offer trial mixes, mock-ups and site testing to validate appearance and performance prior to bulk delivery. Our technical visits include sampling, slump checks, and recommendations for admixtures to control open time, workability and set time in different weather conditions.

Why Choose Page International Mortar

Choosing our mortar means choosing consistent quality, practical technical support, and supply systems designed for real-site conditions. You save time with ready-to-use mixes, lower costs through reduced waste, and improve durability with mixes optimised for the CEMAC climate. Every delivery is backed by testing, documentation and a technical team that understands local construction practices.

Get Started

To specify Page International mortar on your next project, contact our technical sales team. We will advise the most suitable product, provide trial mixes, deliver material to site, and support placement and curing to ensure the intended performance is achieved. Build with confidence, build with Page International, one wall at a time.